An Electrical Panel Labels PDF provides a clear and organized way to identify circuits, ensuring safety and efficiency. These templates are downloadable and customizable, helping to prevent electrical hazards and ensure compliance with standards.

What Are Electrical Panel Labels?

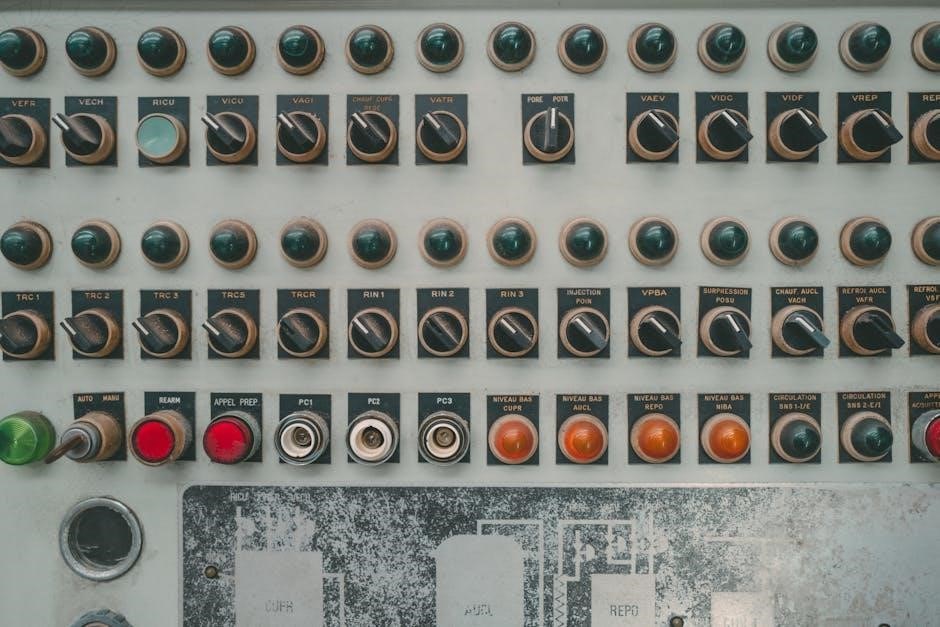

Electrical panel labels are essential for identifying circuits, breakers, and their corresponding connections within an electrical panel. They provide clear information about the circuits, ensuring safe and efficient management of electrical systems. These labels typically include details like circuit names, amp ratings, and device connections, helping to prevent hazards and simplify maintenance tasks.

Importance of Proper Labeling

Proper labeling of electrical panels is crucial for safety, ensuring clear identification of circuits and breakers. It minimizes risks of accidental shocks, fires, and mismanagement during maintenance. Clear labels enhance efficiency, allowing quick identification of circuits, and ensure compliance with legal and safety standards, protecting both people and equipment from potential electrical hazards.

Information Required on Electrical Panel Labels

Electrical panel labels must include the model number, manufacturer details, installer information, installation date, technical specifications, and circuit identification. This ensures clarity, safety, and compliance with standards, making it easier to manage and maintain electrical systems effectively while preventing potential hazards.

Model Number and Manufacturer Details

Including the model number and manufacturer details on electrical panel labels ensures proper identification and traceability. This information is crucial for maintenance, repairs, and parts replacement. It also verifies compliance with industry standards, ensuring the panel meets safety and performance requirements. Accurate labeling helps electricians and technicians work efficiently and safely, reducing potential risks and downtime during electrical system management and troubleshooting.

Installer Information and Date

Documenting the installer information and installation date on electrical panel labels is essential for accountability and record-keeping. This detail helps track the installer’s responsibility and ensures compliance with safety standards. The date provides a reference for maintenance schedules and warranty claims, while the installer’s name and company add transparency for future inspections or troubleshooting, ensuring reliable electrical system management and adherence to regulations.

Technical Specifications

Technical specifications on electrical panel labels include voltage ratings, maximum amperage, and circuit capacities. These details ensure compatibility and safe operation of the electrical system. They also guide load calculations and help electricians understand the panel’s limitations. Accurate specs prevent overloading and enable proper maintenance, ensuring the system operates efficiently and safely, while adhering to electrical codes and standards for reliable performance and compliance.

Circuit Identification

Circuit identification on electrical panel labels specifies which devices or areas each circuit controls. This includes listing appliances, rooms, or systems connected to each breaker. Clear labeling ensures easy identification, enabling efficient troubleshooting and safe maintenance. It helps electricians and homeowners understand the electrical system’s layout, preventing accidental shutdowns and ensuring proper circuit management, while maintaining organization and clarity for all users. This is crucial for safety and functionality.

Types of Electrical Panel Label Templates

Electrical panel label templates come in basic, detailed, and specialized formats. Basic templates list circuits and their purposes, while detailed versions include technical specs like voltage and amperage. Specialized templates cater to unique electrical setups, ensuring clarity and organization for various applications.

Basic Templates

Basic electrical panel label templates provide a straightforward layout for identifying circuits and their purposes. These templates include spaces to label each breaker or fuse, along with the corresponding room or area they serve. Simple and easy to use, they ensure essential information is clearly displayed, aiding in quick identification and maintenance; Available in formats like Excel, Word, and PDF, they offer a fundamental solution for organizing electrical panels efficiently.

Detailed Templates

Detailed electrical panel label templates offer a comprehensive layout, providing additional information such as voltage, amperage, and the specific purpose of each circuit. These templates are ideal for industrial or complex electrical systems, ensuring clarity and precision. They help in maintaining detailed records and are available in editable formats like Excel, Word, and PDF, making them highly customizable for specific needs.

Specialized Templates

Specialized electrical panel label templates cater to specific industrial or complex electrical systems, offering advanced features like color-coded labels, circuit symbols, and detailed diagrams. These templates are designed for high-voltage panels, marine systems, or custom installations. They provide enhanced organization and safety, ensuring compliance with industry standards. Many are available in PDF, Excel, or Word formats for easy customization.

Advantages of Standardized Templates

Standardized electrical panel label templates enhance safety, efficiency, and compliance. They ensure consistency, reduce errors, and improve readability, making it easier to identify circuits and maintain electrical systems effectively.

Enhanced Safety

Standardized templates improve safety by ensuring clear and consistent labeling of electrical panels. This reduces the risk of accidental shocks or fires during maintenance or emergencies. Clear identification of circuits and components allows for quick, informed decisions, minimizing hazards and ensuring compliance with safety standards.

Improved Efficiency

Standardized electrical panel labels enhance efficiency by providing clear, consistent, and easily understandable information. This allows electricians and maintenance personnel to quickly identify circuits, reducing downtime during repairs or upgrades. Organized labeling streamlines troubleshooting, ensuring faster resolution of issues and minimizing operational disruptions.

Compliance Assurance

Proper electrical panel labeling ensures compliance with legal and regulatory standards, such as those outlined in the National Electric Code (NEC). Using standardized templates guarantees adherence to required specifications, avoiding potential legal issues. Clear and accurate labels help meet safety and compliance requirements, ensuring installations are up to code and approved by regulatory authorities.

Legal and Regulatory Requirements

Electrical panel labels must comply with standards like the National Electric Code (NEC) and local regulations. Proper labeling ensures adherence to safety protocols and avoids legal penalties, guaranteeing installations meet regulatory requirements and industry standards for clear identification and documentation.

Relevant Standards and Codes

Electrical panel labels must comply with standards like the National Electric Code (NEC) and International Electrotechnical Commission (IEC) guidelines. Specific codes, such as NEC 70 for safety and IEC 60445 for label durability, ensure proper identification and prevent hazards. Adherence to these standards is mandatory for legal compliance and workplace safety, guaranteeing clear and consistent labeling practices across installations.

Color Coding and Labeling Standards

Color coding on electrical panels enhances safety and quick identification. Standards like NEC and IEC specify colors for phases (e.g., black, red, blue) and neutral/ground (gray, white, green). Labels must use contrasting colors and clear fonts, ensuring readability. Consistent color schemes and compliant labeling practices reduce errors and improve efficiency in electrical systems management and troubleshooting.

How to Fill Out Electrical Panel Label Templates

Start by gathering information from building plans and electrical diagrams. Fill the template with circuit details, ensuring accuracy. Label each panel and circuit clearly using a label maker or pen, matching the template’s data for consistency and compliance.

Gathering Necessary Information

To accurately fill out electrical panel label templates, gather details from building plans, electrical diagrams, and load calculations. Collect circuit information, model numbers, manufacturer details, and installation dates. Ensure all data matches the panel’s configuration for clarity and compliance with safety standards. This step is crucial for creating precise and reliable labels.

Step-by-Step Completion Guide

Start by reviewing the template and understanding its layout. Enter the panel name, location, and model number. List each circuit breaker, assigning corresponding rooms or devices. Include technical specifications like voltage and amperage. Cross-reference with electrical diagrams to ensure accuracy. Double-check all details before finalizing. Use a label maker or permanent marker for clear, durable labels.

Tools for Creating Electrical Panel Labels

Tools for creating electrical panel labels include label makers, PDF editors, and specialized software. These tools ensure professional, clear, and durable labels for safe identification.

Manual Labeling Methods

Manual labeling involves using permanent markers or label makers to clearly identify circuits on electrical panels. Printable templates can be filled out by hand, ensuring each breaker or fuse is accurately labeled. This method is straightforward and cost-effective, though it may lack the uniformity of digital tools. Proper handwriting and durable materials are essential for longevity and readability.

Software and Digital Tools

Software and digital tools simplify the creation of electrical panel labels by offering pre-designed templates and customization options. Tools like CocoDoc enable users to edit, fill, and print labels in PDF format. These solutions enhance consistency, reduce errors, and save time, ensuring labels are clear, professional, and compliant with safety standards.

Common Mistakes to Avoid

Common mistakes include incorrect or missing information, poor readability, and improper placement of labels. These errors can lead to safety hazards, inefficiency, and non-compliance with regulations, emphasizing the need for careful preparation and adherence to standards.

Incorrect or Missing Information

Incorrect or missing information on electrical panel labels can lead to safety hazards, inefficiency, and non-compliance with regulations. Common errors include omitting model numbers, mislabeling circuits, or providing vague descriptions. This can result in confusion during maintenance or emergencies, potentially causing electrical shocks or fires. Accurate and detailed labeling is essential for safe and effective operations.

Poor Readability and Placement

Poor readability and improper placement of labels can hinder quick identification of circuits. Using small fonts, inadequate color contrast, or placing labels in hard-to-reach areas can lead to confusion. This can delay maintenance or emergency responses, increasing the risk of accidents. Labels should be clear, large, and strategically positioned for easy visibility and accessibility.

Best Practices for Labeling

Use durable materials and clear fonts for long-lasting readability. Ensure regular updates and audits to maintain accuracy. Proper placement and visibility are crucial for quick identification and safety compliance.

Using Durable Materials

Using durable materials like polyester or vinyl ensures long-lasting readability. These labels resist heat, moisture, and chemicals, making them ideal for industrial settings. Choose UV-resistant inks to prevent fading. Adhere to labeling standards for compliance. Apply labels using industrial-grade tools or professional printing services to ensure proper adhesion and avoid air bubbles or creases.

Regular Updates and Audits

Regular updates and audits ensure accuracy and compliance with safety standards. Periodically review and update labels to reflect system changes or modifications. Use labeling software to maintain consistency and clarity. Perform visual inspections to verify that all labels are legible, correctly placed, and match the electrical system configuration. This practice minimizes risks and ensures reliable operation over time.

Customization Options

Electrical Panel Labels PDF can be tailored to specific needs, offering various formats like Excel, Word, and PDF. Use label makers or software for precise customization, ensuring clarity and relevance to your electrical setup.

TAILORING Templates to Specific Needs

Electrical Panel Labels PDF templates can be customized to fit specific panel configurations. Users can edit details like circuit names, amp ratings, and installer information. Advanced customization allows for adding logos or color-coding, ensuring labels are clear and relevant to the setup. Printable templates in formats like Excel or Word make it easy to adapt designs for unique electrical systems, ensuring precision and compliance with standards.

Advanced Customization Techniques

Advanced customization involves using software to add complex details like circuit diagrams, QR codes, or dynamic data. Tools like Adobe Acrobat or specialized label makers enable precise edits, ensuring labels are both informative and visually appealing. This approach allows for tailored designs, enhanced readability, and seamless integration with existing electrical systems, optimizing functionality and accessibility for users.

Electrical panel labels PDF are essential for safety, efficiency, and compliance. Proper labeling ensures clear circuit identification, reducing risks and downtime. Using standardized templates guarantees consistency and accuracy, making them a vital tool for any electrical setup. Always prioritize detailed and durable labels for long-term reliability and adherence to regulations.

Final Thoughts on Effective Labeling

Effective labeling of electrical panels is crucial for safety, efficiency, and compliance. Clear identification ensures quick circuit recognition, reducing risks during emergencies. Standardized templates promote consistency, while durable materials enhance longevity. Regular updates and audits maintain accuracy, supporting long-term reliability and adherence to regulations. Proper labeling is a cornerstone of electrical system management and maintenance.